Linear Drives

How well and how precisely a machine functions depends on the quality of its linear guidance. Furthermore, linear technology also normally has a direct influence on the overall durability a machine. In traditional mechanical engineering, the manufacture of dovetail guides and flat guides was associated with huge costs. High manual and manufacturing technology skills were therefore required in companies.

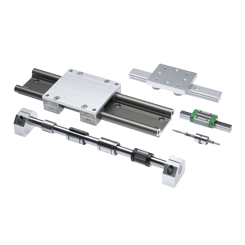

Today, we have at our disposal "kits" produced in huge quantities containing machine elements which allow us to make linear guides of the highest quality: we can manufacture them efficiently, spending the minimum amount of time and little money.

There is also the additional benefit that these guiding elements only cause minimal rolling friction instead of dynamic friction. This, in turn, helps save energy and allows for the use of smaller drives. Hardened shafts and rails are impressively durable. However, they are not the deciding factor for the durability of the machine: after all, modern guiding elements can be replaced at any time.

Hoisting and Positioning Systems

Electro-mechanical lifting cylinders are a sensible alternative to hydraulic cylinders. Hoists of up to 1,500 mm can be achieved with the most diverse loads and speeds. The power supply can range from 24 V DC to 230 V AC. They can also be used in inaccessible areas as no dedicated lines are required and it is possible to use battery power supply.

Positioning systems are compact and economical general solutions for driven guides. The products available range from compact carriages without drive to highly dynamic, multi-axis systems with linear motor drives.

Linear Service Centre

The Linear Service Centre makes up an integral part of our range of services!

We created our Linear Service Centre so that you can make the most of the linear guidance within the modular design principle.